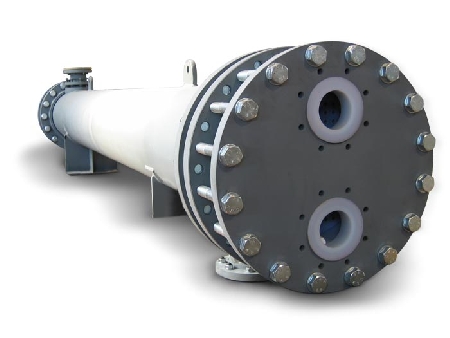

FLOWSiC ® patented shell and tube heat exchanger of 30,0 m2 for liquid/liquid exchange (Patent USA Nr.: US 6,904,959 B2)

The silicon carbide heat exchanger represented in the photo was made for an international customer related to 2 heat recoveries where are requested high corrosion resistance, absence of metal releases and a separation room between the two process fluids.

Each separation room is fitted with a lateral threaded connection to monitor eventual leakage through an alarm or simply through a sight indicator.

The main components of the FLOWSIC® heat exchanger are:

- shell according to norm TEMA type E, DN 16” x 3800 mm in CS PTFE lined

- bundle composed of 176 silicon carbide Hexoloy ® SA SiC tubes diam. 14 x 1,5 mm x 4000 mm including baffles and spacers in PTFE

- heads according to norm TEMA type AL, DN 16” in CS PFA lined

- primary and compression tube-sheets in CS PFA lined

- nr. 352 sealing packages each composed of double Kalrez ® Spectrum TM O-rings (for a total of nr. 704 O-rings) with PTFE intermediate sleeve

Both recoveries have been tested to our factory, with positive result, at 10 bar for 1 hour at the presence of a notify part, according to norm PED 97/23/CE – Category IV, module G.